Novinky

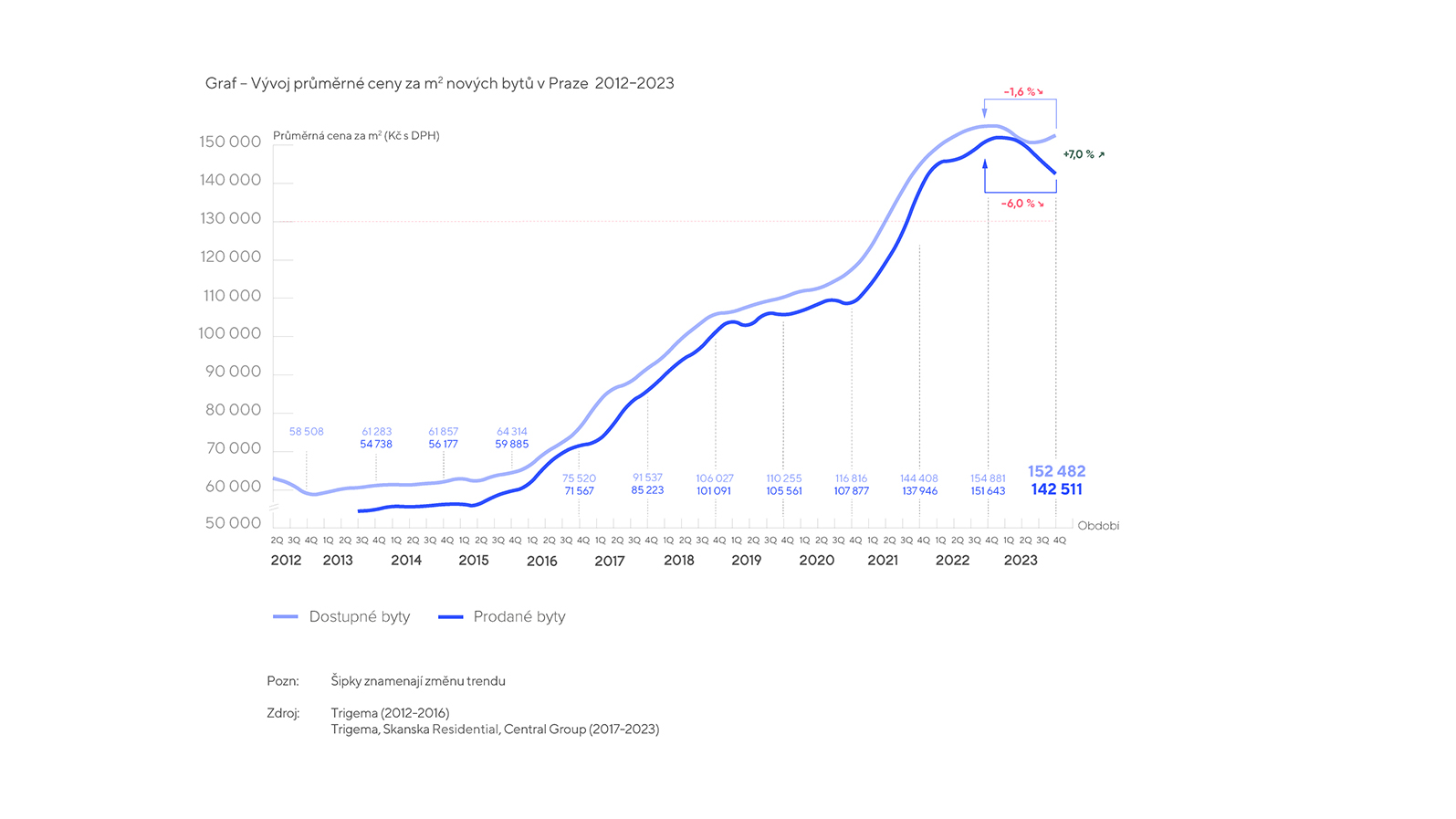

Trh s novými byty se vrací na úroveň před krizí, meziročně se prodalo o třetinu více

Modřanský Cukrovar II.

Penta Real Estate dokončila největší akvizici ve své historii

Investoři mohou participovat na mezaninovém financování pro OC Perla

PSN ZLEVŇUJE VŠECHNY BYTY

Rodinné domy Satalice

Rezidence Chodovec

JSME TADY PRO VÁS

Jste na webových stránkách, kde byste měli najít každý aktuální developerský projekt, který se objevil či objeví na českém bytovém trhu, ať už se jedná o rezidenční bydlení, kancelářskou budovu nebo jinou komerční plochu, která je součástí bytového projektu. Pokud najdete developerský projekt, který na našich stránkách není, budeme rádi, jestliže nás na něj upozorníte. My jej zdarma pro náš server zpracujeme a uvedeme na našich stránkách, protože naší zásadou je, abyste zde na jednom místě našli všechno, co se v této oblasti u nás objeví.

Někteří místní obyvatelé tvrdí, že kasina negativně ovlivňují hodnotu nemovitostí v jejich okolí online-casinocz.com/nove-online-casino/ . Hazardní hry v kasinech například zvyšují míru kriminality a hodnotu domů v okolních oblastech. Může také vést k problémům s dopravou a dopravním přetížením. Z tohoto důvodu se mnoho lidí staví proti výstavbě kasin ve svém okolí. Někteří obyvatelé však tvrdí, že je třeba zvážit, zda kasino ovlivní danou oblast. Odpověď vás možná překvapí. Tato debata má však polarizující charakter.

Fair go casino. It is a licensed online gambling site that provides a fair playing environment and offers players a good selection of games. This casino offers a generous welcome bonus to new members and rewards loyal members. It is owned and operated by Deckmedia, which operates a number of gaming sites including Uptown Aces, Miami Club and Spartan Slots. The casino is powered by Real Time Gaming and offers prime notch Australian pokies with great graphics and sound.

Nové kasino se však potýká s řadou problémů. Za prvé, obyvatelé okolních čtvrtí jsou proti projektu. Někteří tvrdí, že to povede ke zvýšení kriminality, snížení hodnoty domů a zvýšení počtu lidí, kteří mají problémy s hazardem. Za druhé, kasino podle nich povede k hustému provozu a zvýšené kriminalitě. Není však známo, zda nové kasino ovlivní hodnotu nemovitostí v oblasti nebo dopravu. Komunitní poradní sbor 78 provedl v únoru průzkum mezi 378 obyvateli ohledně kasina a zjistil, že téměř tři čtvrtiny z nich jsou proti tomuto projektu.

Klientské Změny

SHOWROOM StudioIn+

- Na ploše 400 m2 široká nabídka dveří, podlah a dalších produktů

- Individuální přístup ke všem zákazníkům a speciálně i k developerům

- Nastavení výběrové kombinace standardů pro developery a B2B program

- Budoucí řešení interiéru nejen on-line, ale i pohledem brýlemi s virtuální realitou

Nové Byty

Hledáte nové byty v novostavbách developerských projektů, které jsou třeba ještě ve fázi přípravy, zahájení prodeje nebo počátku výstavby? A chcete být první, kdo si bude vybírat z toho nejlepšího v nabídce? Pak jste zde na správném serveru.

See ProjectsRodinné Domy

Nechcete byt, ale hledáte rodinný dům? Pak si u nás můžete vybírat z nabídky řadových domů, dvojdomů či solitérů na klíč anebo pozemků v developerských projektech, kde si dům můžete postavit sami podle svého přání.

See ProjectsKomerční Projekty

Chcete mít kancelář, prodejnu nebo provozovnu služeb v místě nebo blízko vašeho bydliště? Pak hledejte v naší nabídce rezidenčních projektů, které obsahují komerční plochy, nebo v samostatných developerských projektech administrativních a komerčních budov.

See Projects